Reinventing Workplace Efficiency With Heavy-Duty Casters

What Are Casters and Why Do They Matter?

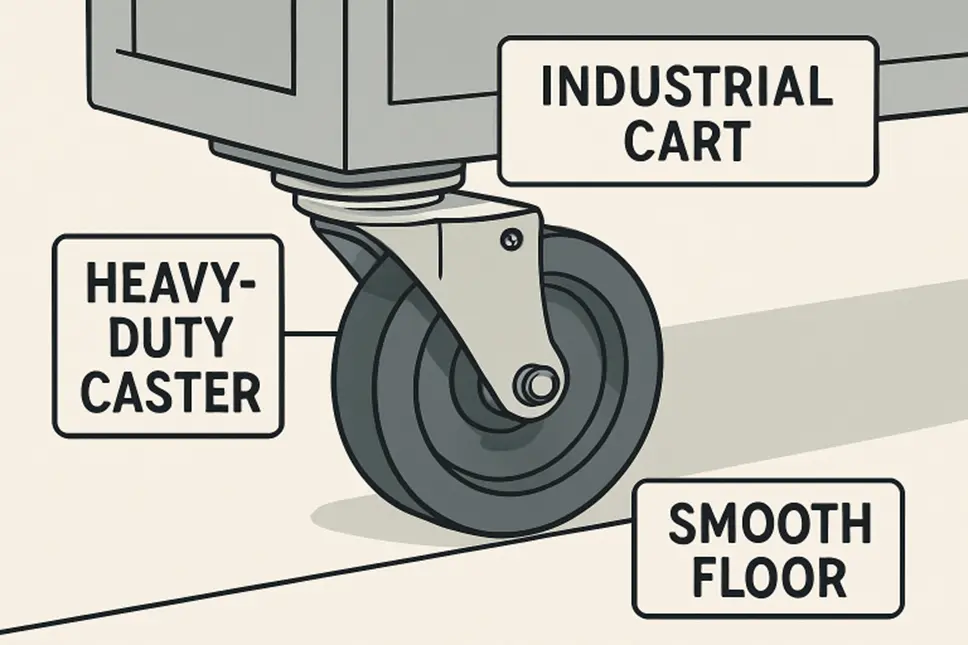

Casters are small wheels attached to the base of equipment, furniture, or machinery, allowing for smooth movement and improved maneuverability. In modern workplaces, where efficiency and adaptability are critical, using the right casters can dramatically reduce employee strain, speed up workflows, and prevent damage to floors and equipment. Heavy-duty casters, in particular, are designed to handle substantial weight while maintaining stability and ease of motion, making them essential in industrial and commercial settings.

High-quality components like Hudson bearings are crucial to maximizing performance and caster functionality. These bearings reduce friction and wear, enabling heavier loads to move effortlessly and safely. By combining robust construction with precision-engineered bearings, workplaces can optimize productivity, minimize downtime, and enhance overall operational efficiency.

Choosing the Right Type for Every Application

Casters are far from one-size-fits-all. They are categorized primarily as swivel casters, which allow for whole 360-degree movement, and rigid casters, which move strictly in a straight line. Each type serves a specific operational need: swivel casters make navigating tight spaces and sharp turns effortless. In contrast, rigid casters offer stability for heavier loads or when only straightforward motion is required. Beyond type, factors such as the floor surface, load capacity, frequency of use, and environmental conditions (like exposure to chemicals or moisture) must be considered. Accurate pairing of caster and application ensures productivity, safety, and cost-effectiveness.

Benefits of Casters in the Modern Workplace

Casters offer several benefits in the modern workplace, including increased efficiency, reduced injury risk, and flexible configurations. They reduce material transportation time, help companies adhere to OSHA’s material handling guidelines, and can adapt to new layouts or production needs. Investing in caster-enabled environments increases employee satisfaction and retention and contributes to a more organized and safer workplace culture.

How Caster Material Impacts Performance

The material composition of a caster influences everything from ease of movement to durability in harsh conditions. Common materials include rubber, polyurethane, cast iron, and stainless steel. Rubber casters excel at absorbing vibration and noise, protecting sensitive equipment and creating a quieter environment. Polyurethane, a favorite in modern logistics, merges durability with floor protection and performs well under heavier loads. Metal casters, such as those made from steel or iron, are reserved for environments with extreme temperatures or corrosive substances, where other materials would rapidly degrade.

Safety and Ergonomics: Tips for Safer Working Environments

To ensure safer working environments, inspect casters regularly for debris, use locking casters for heavy equipment, train staff on proper handling techniques, avoid overloading carts, and integrate comprehensive maintenance and safety training. These measures minimize costly incidents and ensure operational continuity, ensuring a smoother operation and reducing worker strain.

Maintaining Casters for Long-Lasting Performance

Maintaining casters goes beyond a visual check. It requires proactive steps such as bi-monthly lubricating swivel bearings and axles, removing buildup from wheel treads, and regularly tightening hardware. Immediate replacement of worn wheels or damaged components is vital for preventing sudden downtime. These small, consistent efforts extend caster lifespan, maximize equipment uptime, and help businesses avoid disruptive surprise repairs.

Future Trends in Industrial Mobility Solutions

Advances in smart caster technology and an increased emphasis on sustainability shape the future of workplace mobility. Next-generation casters integrate sensors that track load, position, and status in real time, enabling predictive maintenance and supporting automated workflows. As more industries integrate robotics, casters are evolving to offer even lower maintenance and quieter operation, made from recycled or eco-friendly materials.